What are culturally and economically appropriate recommendations?

Engineering Ministries International teams are routinely asked to comment on the existing construction at a ministry site. What happens when a building proves to be unsafe even for its current purpose? Can EMI teams speak into the situation with realistic recommendations?

On a recent EMI project in north India, our client had just completed the construction of a new primary school. The U-shaped building, opening onto a large courtyard, was designed and constructed prior to EMI’s involvement. The school was intended to have two storeys, but the client had not attempted something of this scale before. Neither had the local builder.

Uncovering a vulnerability

Construction did not go well. The local builder ended up being replaced prior to the pouring of the first floor slab. The lack of a professional design coupled with an inexperienced contractor resulted in sub-par construction. The client began to doubt whether the building could support the originally planned second storey. He asked the EMI team—on-site to design new buildings for the expanding school campus—to offer an opinion. Could a second storey be added to this existing school building or not?

The EMI team inspected the building and reviewed photos taken during construction. We were quickly able to confirm that a second storey should not be added. We also discovered that the cast-in-place reinforced concrete-framed school was vulnerable to collapse in the event of a strong earthquake. Not only did the first contractor form and pour the roof level beams separate from the slab, but these beams were nearly 10” too low. In order to reach the desired height, the second contractor laid three courses of brick on top of the beams prior to forming and pouring the roof slab. This innovation was concealed by plaster at the time of our visit. Inspection of construction photos brought the condition to light. While unorthodox, this method is stable under gravity loading. However, if earthquake shaking was to cause the three brick courses to crack and be displaced, the reinforced concrete roof slab would be supported by only columns at the corners. This could cause punching shear failure and potentially collapse the roof slab.

What is realistic?

This scenario illustrates the position that we as EMI staff and volunteers often find ourselves in. We must be aware of our responsibility as design professionals to inform our clients and/or the public of the hazard. We need to make recommendations to mitigate that hazard, but are these recommendations realistic?

In my home country, occupation of this school building would likely not be allowed until the structural safety issues were fully remediated. Third-party engineers would be hired, and reinforced concrete shear walls with large footings would be designed. These would be installed in place of the existing column, beam and infill brick walls at many locations throughout the building. The retrofit would be designed according to thoroughly researched and legally enforced building codes. In the event of an earthquake, the stiff shear walls would attract most of the earthquake-induced forces, and the building would not be in danger of collapse.

But is such a remediation realistic at a small town in north India? Throughout the 17 years of EMI’s presence in India, we have learned through trial and error what level of detail we should communicate to contractors. Often, in the early days, structural plans equivalent to the detail required in North America were produced. In many of those cases, the plans were labeled as “foreign” by the contractor and simply ignored. Today we have greatly reduced the complexity of our structural designs and utilize Indian building codes. Still, we regularly hear haggling comments from contractors like, “are you sure 20mm bars are required for the columns? 16mm or 12mm is enough…” We have learned to identify the 2 or 3 items that are the most important to structural safety of the building. In seismic zones in north India, these items included the column reinforcing details (bar size, splice location and stirrup spacing), beam stirrup spacing, and potential soft stories caused by infill wall location. If good design in these areas is to be implemented, the client and contractor – who have near total control over project execution – need to be convinced why these items are important.

So, if the shear wall remediation described above were to be recommended to our EMI client, little good would come of it. Although technically effective, such a solution would be deemed too costly and too disruptive to be installed. The building would remain in its existing state of vulnerability. Rather, we must make suggestions that start from the local construction practice that build toward hazard mitigation. With these considerations in mind, several recommendations were made to the school client which follow to below.

Recommendation #1

Develop an earthquake drill for students and teachers:

All schools have various safety drills: fire, tornado, security lockdown, etc. Schools in seismic zones should have earthquake drills so that students know how to react. In many countries of the world, students are taught to “Drop, Cover & Hold” to protect themselves from falling objects. But in this case, due to the architectural layout, students are to exit the classroom as quickly as possible and gather in the courtyard away from the building.

Why are engineers making recommendations about safety drills? Working in a cross-cultural environment with EMI, solutions are often not required to be technical. Sometimes a simple behavioural change (which costs the client almost nothing) can be quite effective at reducing the hazard to the people involved.

Recommendation #2

Undertake a relatively minor modification to the building:

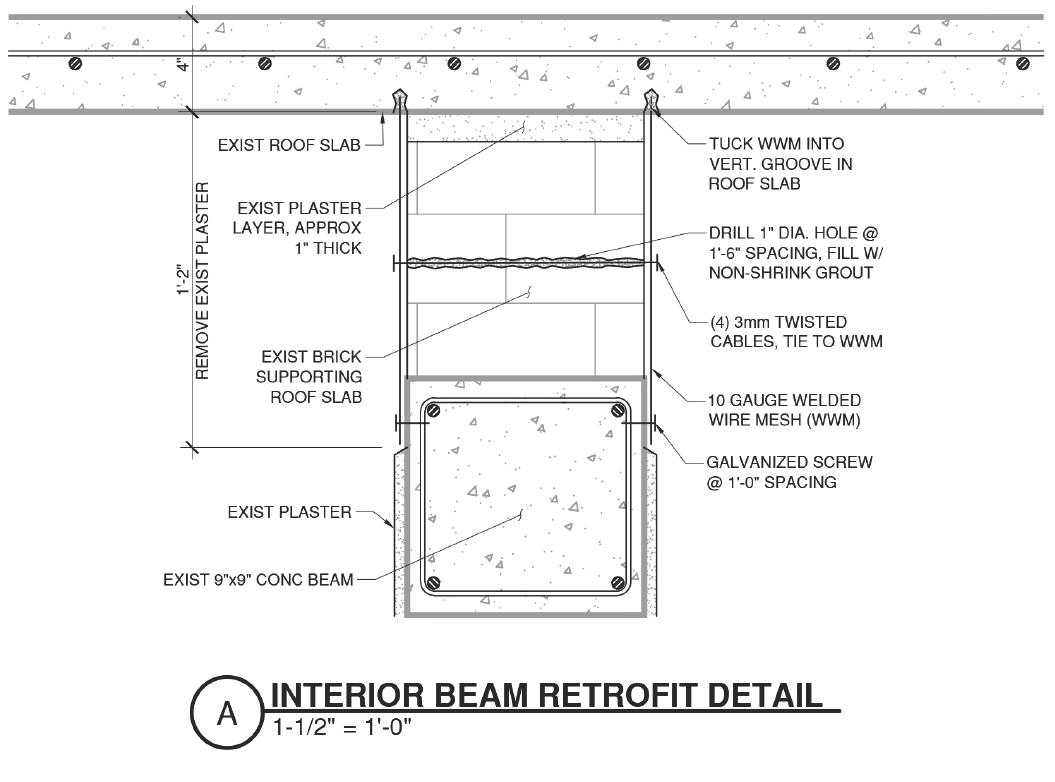

Remove the plaster from the 3 courses of brick between the roof beam and roof slab and install 10-gauge welded wire mesh beneath a fresh layer of plaster. The mesh would be anchored to the beam below with screws, tucked into a vertical groove in the slab above, and tied to the mesh on the other side of the wall with a through-tie.

This retrofit will allow the slab to remain supported by the bricks for a longer time during sustained earthquake shaking. Compared to the shear wall remediation this is certainly minor. However, it does represent a significant effort requiring more than 1500 linear feet of repair. The client is planning on doing it room by room during school holidays.

As design professionals who work outside the professional environments we were educated and trained in, it is vital to recommend solutions that can actually be implemented. Although the risks may not be completely eliminated, our realistic recommendations to the client will substantially reduce the risk to the school. And the relationship continues, allowing us to serve them with technical advice as their ministry expands.

The EMI Fund

The EMI Fund supports all that we do at EMI. With a strong foundation, we can keep designing a world of hope.

EMI Tech is looking for contributors – write to editor@emiworld.org with your topic and article outline.