Creating sources of water through designing sustainable and safe earthen dams.

The concept of an earthen dam is not a new one. Human beings have mounded up large quantities of earth for the impoundment and diversion of water for centuries. Largely unchanged in their design and complexity, these earthen dams and levees were invaluable for the creation of accessible, large quantities of precious water. These early dams were not “engineered” in the modern sense of the word and were subject to catastrophic failure during flood events. In the 20th century, however, the early soil science that eventually became modern geotechnical engineering gave rise to safer, engineered earthen dams that are of better quality and make better use of this precious resource.

In north-central Nigeria, this kind of modern dam is a dream for the Haven of Hope clinic and school. Climatic conditions afford the region two extreme wet/dry seasons, with the summer months receiving an average of 50 inches of rain. The rain then abruptly ends at the advent of winter, and by the time spring arrives the region is covered in a fine, reddish brown dust. Fresh crops are limited to whatever can thrive in the “dust bowl” of the dry season. Compounding the trouble is the proximity to potential violence from Boko Haram and other terrorist activity.

It is in this world that the Haven of Hope exists. This ministry is truly a haven: an outpost of security, safety, and hope to the villages on the outskirts of Jos, Nigeria. The ministry consists of a clinic, a day school for children (pre-K through high school), a water distribution facility, and a Bible college. The property also happens to contain an eroded tin mine. In the days of British colonialism, the hills around Jos were heavily mined for tin. Over the years, many of these mines have caved in and eroded, creating vast gullies and ravines that scar the landscape. As mentioned, one of these ravines happens to be on the property of the Haven of Hope. EMI was brought on to perform a feasibility study for a large earthen dam in the ravine that would create a freshwater reservoir.

While performing a feasibility study or design, the two primary failure mechanisms to evaluate are “piping” and overtopping. Piping occurs when the seepage force at the downstream face of the dam becomes too great. The higher the seepage force, the higher the potential for the water to “pick up” soil particles, causing internal paths to form within the dam. Overtopping occurs when the water level exceeds the height of the dam and flows over the crest, or top. If either of these conditions occur and continue unchecked, they will wash out the face of the dam.

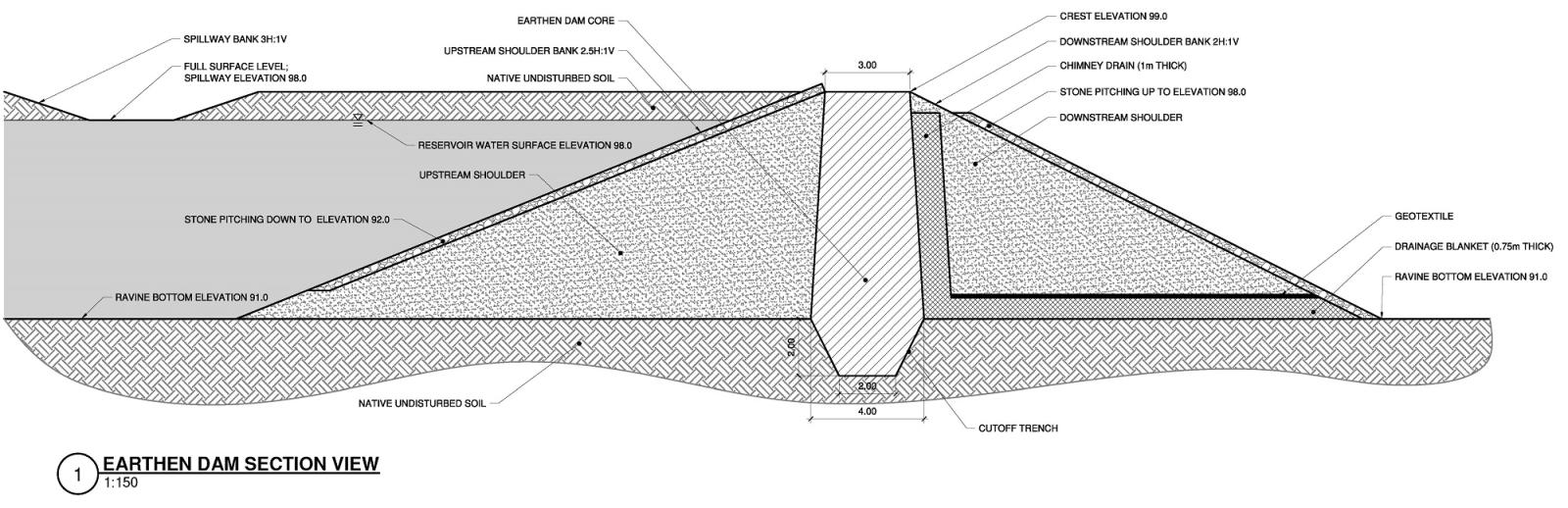

To avoid piping and other detrimental results, soil selection is vital. Therefore, a soil analysis should be performed prior to any design calculations in order to determine the suitability of the local material for use as fill material. In a “zoned” embankment, the earthen dam cross-section consists of three primary vertical layers; the keystone of which is the core. The core creates an impermeable or semi-impermeable wall in order to slow the seepage through the dam. The engineering behind an earthen dam is to control and mitigate the rate of seepage and ensure that all seepage is properly channeled safely to the downstream toe. The core is comprised of the highest quality and least permeable soil available.

In the area of Nigeria under consideration, the defining soil is laterite, which is a clayey sand (USCS SW-CL or SP-CL). This soil type is appropriate to serve as a core when properly screened. Percolation and field seepage tests indicated that the locally available laterite is best defined as “semi-impermeable.” A standard-sized sieve, hydrometer, proctor, and a Casagrande’s liquid limit device are not items easily packed into checked baggage for an EMI trip, so the most efficient way of classifying soils in the field is an ASTM visual method. This method is only a rough estimate and will not produce exact numbers, but someone with experience in soil mechanics can classify with enough accuracy to produce solid design assumptions. Specifically, these include the permeability of the soil and the soil characteristics that affect the core’s susceptibility to internal erosion. These will have profound effect on the sizing and design of the earthen core.

The upstream, or reservoir, section of the zoned embankment can consist of similar soil as used in the core, since the rate of seepage is the primary concern at this point in the design. However, the downstream section must consist of a more permeable material than the core in order to reduce the seepage gradient. As mentioned above, the control of seepage is key to the evaluation and design of the embankment itself. A soil with a higher hydraulic conductivity will reduce the seepage pressure in the downstream face. Further, a “chimney” drain and drainage blanket (see dam cross section above) will capture the seepage as it flows through the core and expedite the flow of the water down the chimney and safely out of the toe of the dam.

In order to circumvent overtopping, a properly sized spillway is paramount. The spillway routes excess water safely around the embankment and discharges it well beyond the downstream toe. From a design standpoint, the spillway is simply an open channel whose dimensions are governed by the peak flood discharge. Once a flood event is calculated, the Rational Method (Q=CiA) can be utilized if the properties of the watershed allow for it. It is critical to select an appropriate flood event and to be conservative in the selection of coefficients for the calculation of the peak flood discharge. The dam at the Haven of Hope is close to the exterior wall of the school compound, and the spillway bank was located only 6 meters from the wall. Therefore, this proximity dictated a conservative approach. In the end, the spillway dimensions were oversized, which allows the channel to absorb the discharge from a larger than typical flood event.

Constructing the dam will involve evaluating the local soils further, utilizing soil compacting equipment and maintaining a rigorous quality control system. In the end, the reservoir created by the dam will hold, at full pool, 23 million liters of fresh water. The reservoir can be used for aquaponics, creating not only a learning environment and training center for the Haven of Hope students, but also a source of vital protein. The reservoir also provides an accessible place from which to draw water for the irrigation of vegetables during the dry season instead of relying on the use of deep wells.

It is just short of impossible to move mountains, but sometimes engineers have an opportunity to “make” mountains. These strategically located and carefully constructed masses of earth can provide many improvements to the surrounding landscape, but most importantly they can improve livelihoods and create hope.

The EMI Fund

The EMI Fund supports all that we do at EMI. With a strong foundation, we can keep designing a world of hope.

EMI Tech is looking for contributors – write to editor@emiworld.org with your topic and article outline.