KIUMA’s Hybrid Energy Plant

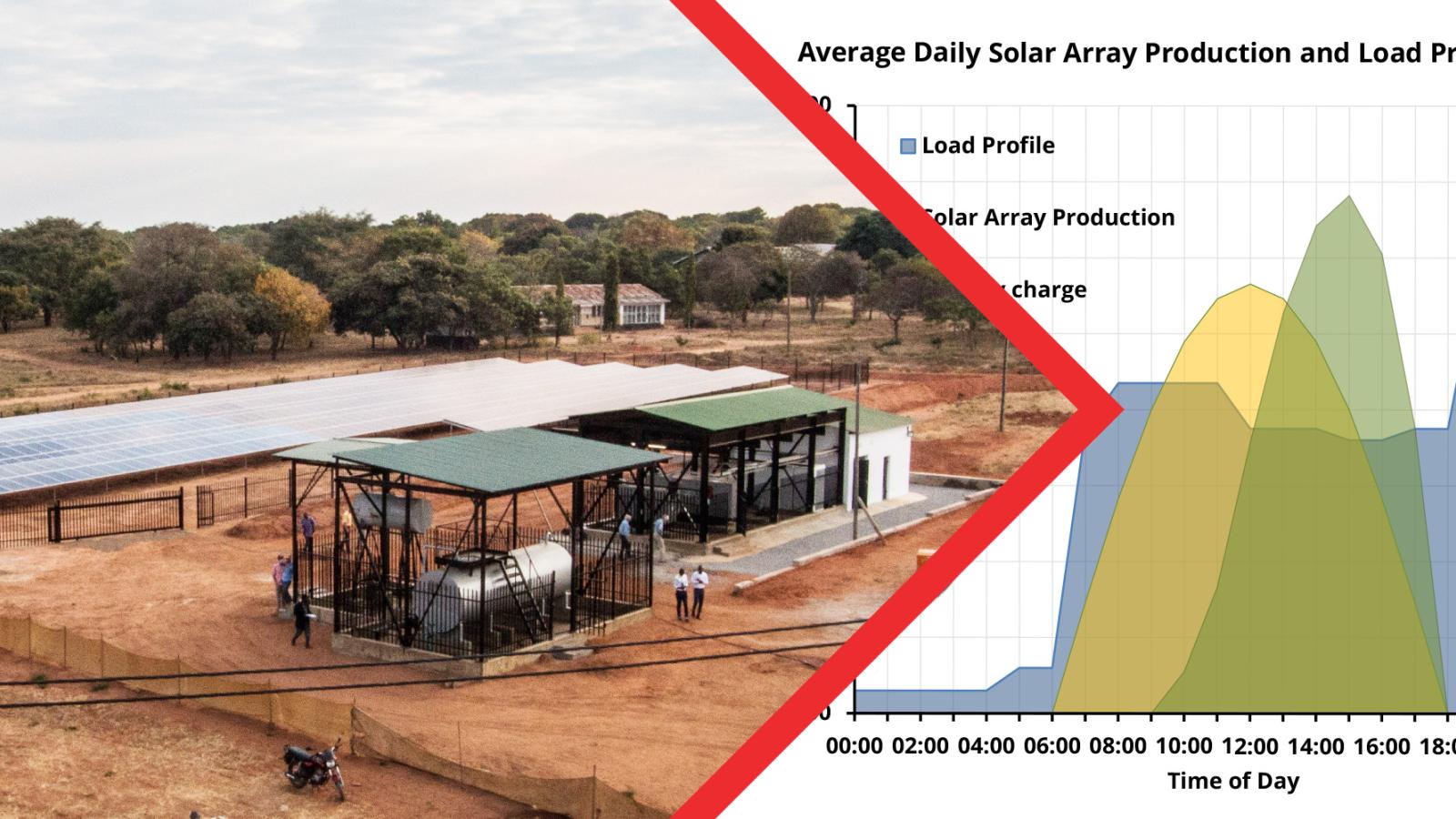

The microgrid at KIUMA was designed with the goal of decreasing the total cost of energy and increasing the long-term reliability and availability of energy for the campus. KIUMA is a ministry amongst the unreached Yao people group of Tanzania. On the large and remote campus are a hospital, Bible school, children’s schools, and a vocational training center.

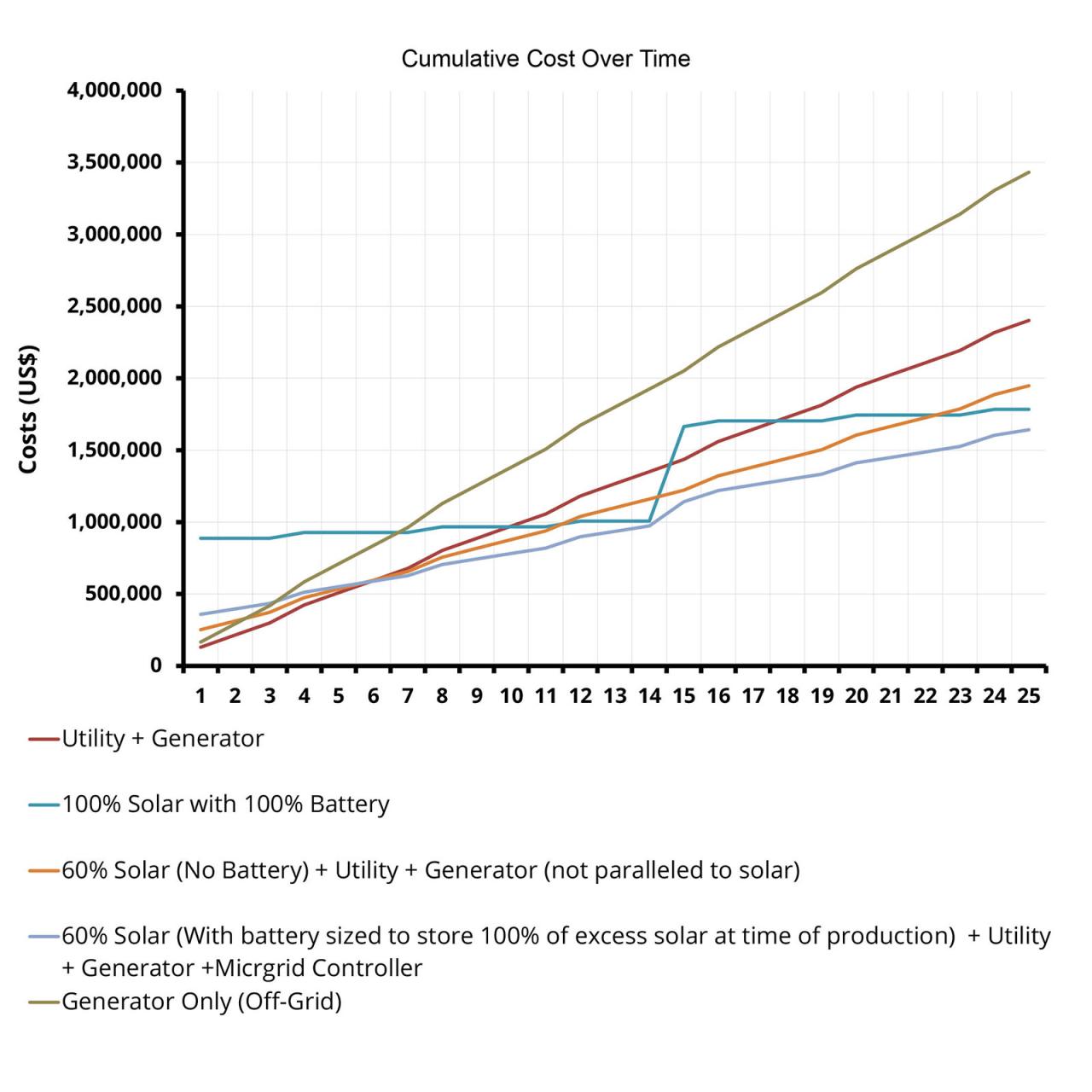

When the site was first visited by EMI, 100% of KIUMA’s power came from diesel fuel costing around $0.27/kWh. In addition, getting fuel to the location during wet season was not easy. This EMI project also included a complete replacement of the electrical reticulation/distribution for the site’s 100+ buildings to address power quality and safety. This article will be limited to discussion of the microgrid.

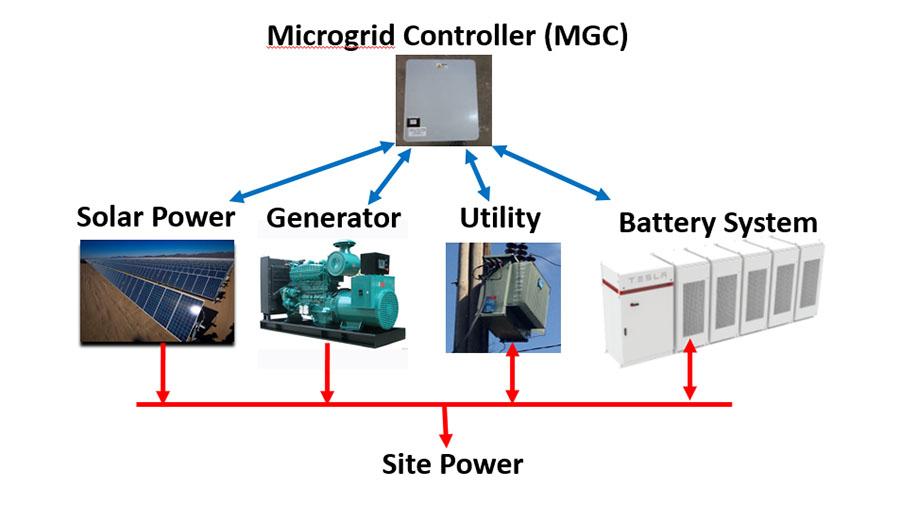

The microgrid at KIUMA consists of a solar power system, diesel generators, utility, and a battery system. All of these are connected to a main AC power busbar. A microgrid controller communicates with all of these systems and controls when each is turned on or off and how much power each is contributing or taking from the microgrid.

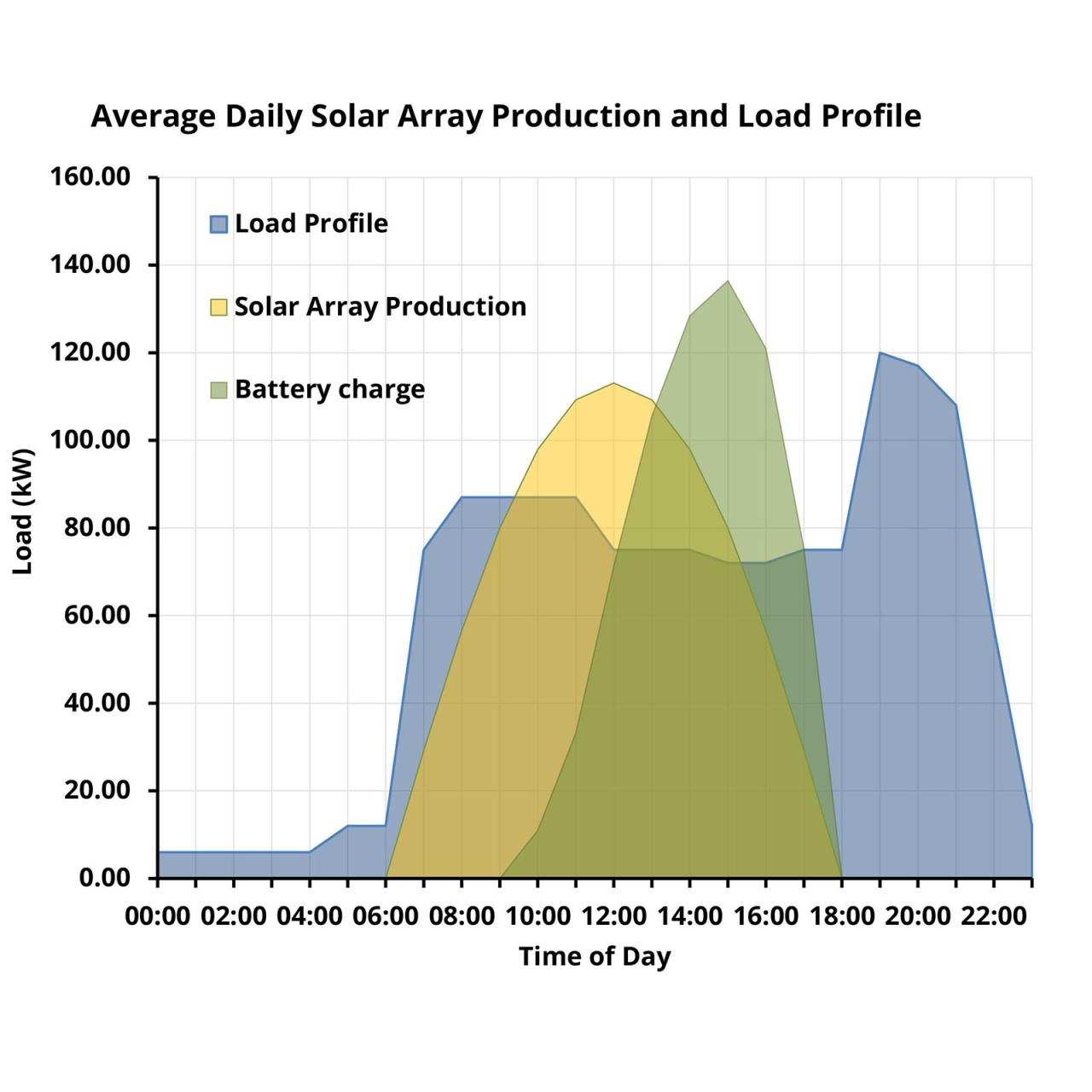

There are three power generation sources in this system: solar power, utility, and diesel generator. As the goal was to minimize the total long-term cost of energy, the microgrid controller is programmed to maximize the use of solar power and minimize the use of the diesel generator. Solar power is the least expensive source of power and diesel fuel the most expensive. Utility cost is between those two.

Following is a high-level system operations overview: On a sunny day, the solar array provides most of the power for the site during daylight hours. During these hours the batteries become charged to 100% with solar power, and any excess power from the solar array is sold back to the utility. During the night hours, the microgrid controller will use the battery system to provide power until they are drained down and then utility power supply is used. The controller will only use the diesel generator if the utility is down.

Throughout the day, the microgrid controller turns systems on and off, controlling the amount each is contributing or taking from the microgrid to minimize the total cost of energy. In cases where one or more of the subsystems are unavailable due to maintenance or lack of sun, it will automatically adjust to operate with any combination of two or more of the four subsystems. The microgrid can also be taken into a manual mode with utility and manual diesel generator backup in case of a failure of the microgrid controller.

The system at KIUMA is an AC coupled system. The solar, battery, generator, and utility subsystems are all individually AC systems. AC coupled specifically refers to how the solar and battery are connected to the microgrid. Solar modules output DC power, so the solar subsystem includes grid-interactive string inverters to convert the DC of the solar modules to AC. The batteries themselves are DC so the battery subsytem includes an AC battery charger/inverter. The solar power and generator can only contribute power to the microgrid, but the battery and utility can contribute or take power from the microgrid.

There are several benefits to an AC coupled system.

- Conversion from 1000VDC to 400VAC at the solar array decreasing the cost and complexity of installation and increasing safety.

- Utility connection on an AC coupled system means that at all times all of the solar power produced can be utilized: some immediately used by loads, some stored in batteries, and some sent to the utility under a net-metering or power purchase agreement. Even if the batteries fail, 100% of the solar can be utilized. Note: The utility net-metering contract for this system is currently on hold by the utility.

- Makes the system more modular. Other than communication and control, it separates the design of the solar system from the battery system enabling future total removal of batteries from the system or adding additional solar or battery capacity without significant redesign to the existing solar or battery systems.

In selecting components for this system, an effort was made to use standard and local parts as much as possible and to design for minimal maintenance. Quality and cost were also taken into consideration. In remote locations like KIUMA, it is not possible to design a good quality microgrid using only parts available in the local village and nearby town. However, contractors and manufacturers that were willing to send installation and maintenance technicians to this remote location were intentionally chosen.

In addition, EMI took an active role as owner’s representative through the project’s completion including detailed design and construction, working in close collaboration with MMM South Africa Trust and a South African contractor to ensure that the design and replaceable commodity parts would be appropriate to the local context. Some examples are listed below:

- Lithium Ion batteries were chosen for their lower maintenance in comparison to other widely available battery technologies and their lower $/Wh over their entire lifetime. A large, reputable manufacturer with presence in South Africa and willingness to provide onsite technical support to this location was selected.

- Standard 72 cell solar modules from a reputable manufacturer were used. Solar modules themselves do not require onsite technical support. They are a commodity so it is important that a standard size (60 cell or 72 cell) is used and some spares purchased.

- Standard diesel generators with components from reputable manufacturers were purchased from a company in South Africa willing to provide onsite installation support to this remote location. Diesel generators are very common in Africa so a local, qualified diesel generator technician can provide maintenance. However, when feasible, generators should be purchased in country from a large, reputable distributor able to provide competent continuing technical support and replacement parts.

- 1000V, 50kW Solar string inverters from a reputable company with significant presence in Africa were used. By choosing string inverters, instead of central inverters, routine maintenance can be performed by a qualified technician on site. Most failures would result in a complete replacement of the unit and therefore do not require an onsite manufacturer technician.

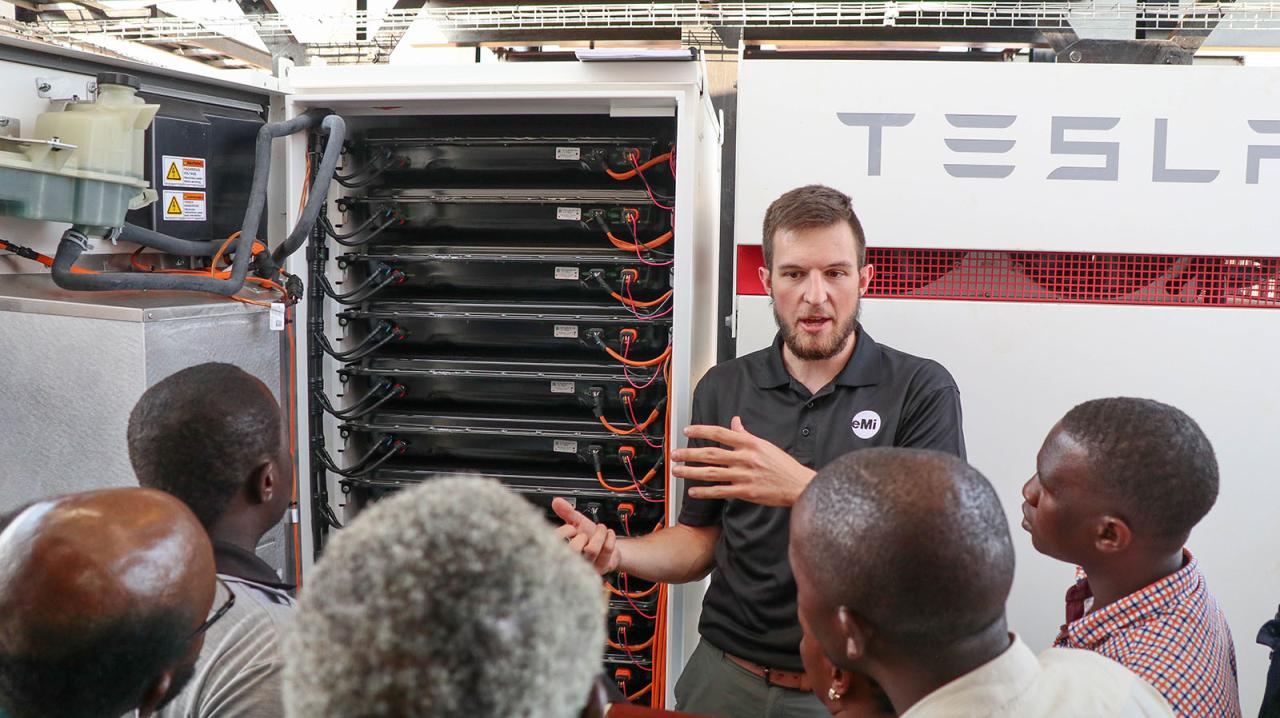

In an effort to ensure the longevity of the system, local labor from KIUMA and the surrounding village was used as much as possible during construction. EMI also provided a full week-long hands-on training to about 30 individuals on site. This training included safety training, names and functions of all main components, system layout, electrical diagrams, operations, maintenance, preventative maintenance checklists, troubleshooting, and teamwork.

EMI’s training used oral methods and assumed very little upfront knowledge to make the training as understandable and attainable as possible for all participants. Training was 100% translated into Swahili and included constant oral evaluation of the students’ comprehension to ensure effectiveness. Those who attended the training included the current electrical maintenance staff, local students, teachers, and administrators. Several goals drove the inclusion of so many in the training:

- encouraging community ownership and support of the maintenance of the system

- making the educational opportunity available to as many as possible

- identifying for the ministry those who would be good candidates for maintaining the system

- sharing the love and message of Jesus

Another key aspect in the sustainability of the system is financial sustainability. Previously power was not being metered or charged for at KIUMA. When the microgrid was installed, prepaid power meters, commonly used in South and East Africa by utilities, were put in place for each customer throughout KIUMA. Each customer is given a set amount of credit (kWh) each month and can purchase additional credit from KIUMA. Credit is entered into the prepaid meter via a numeric code. The customer provides cash to a vendor and receives a code to enter into their meter to apply that cash to their prepaid electric meter. Charging for the power encourages customers to be efficient in their use of power and provides money for the continuing costs of fuel and maintenance required to keep the system running.

The design, component selection, installation, and training process were all done with the goal of long-term power cost reductions and long-term sustainability of the system. Our prayer is that this system will serve KIUMA for many years, increasing the availability and affordability of power and enabling the ministry to become more effective.

The EMI Fund

The EMI Fund supports all that we do at EMI. With a strong foundation, we can keep designing a world of hope.

EMI Tech is looking for contributors – write to editor@emiworld.org with your topic and article outline.