By Ryan Williams, P. Eng.

International Projects Manager, EMI Canada

Designing ways of moving water to where people want and need it, especially moving it uphill, has always been an integral factor in the development of human civilization.

From simple Archimedes screws to modern pumps, the ability to get clean fresh water to site can signal the success or failure of a new development.

Here in Canada, water design is often no more complicated than looking up the information in the relevant government databases or reviewing the surveys, regulations and standards gathered from the local municipal planning department and then using this information and the existing infrastructure to guide the proposed design work.

However, its not quite as simple when working in rural locations in the developing world. How can civil engineers, who honed their skills working in Canada, adapt to design water systems in these developing countries? On an EMI project trip, how do the engineers get the information they need, such as the groundwater depth and bedrock level? What is the required design flow? How will power be provided to the site?

This was the challenge faced by our project team in Uganda as they worked to get the information needed to design a secondary school masterplan meant to serve 400 students and staff for Bless The Children Ministries (BTCM).

With no existing water utilities to connect to, the solution for the team was to design a robust, redundant and reliable water borehole and pump system to provide water for the new school campus.

Trying to get the necessary data to do this, 20 years ago in Uganda would have been nearly impossible. Fortunately, technological advances have led to the creation of publicly available databases, such as Uganda’s Water and Environment Information System (WEIS) that estimates the borehole yield capacity in each district in Uganda.

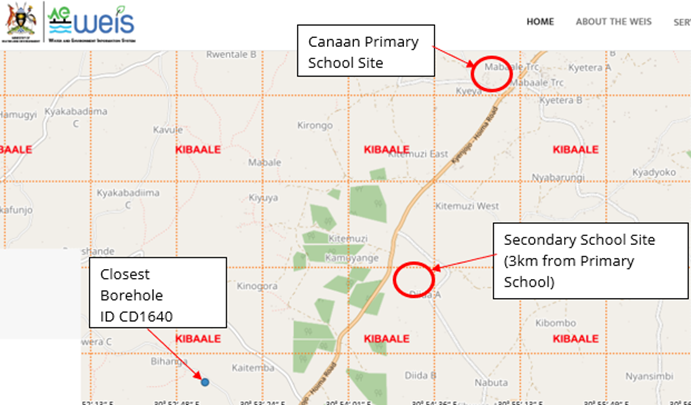

For the BTCM project, the secondary school site is in Mabaale, in the Kibaale district. This site is near an existing community borehole located in the village of Kaitemba, Southwest of Mabaale. See Figure 1.

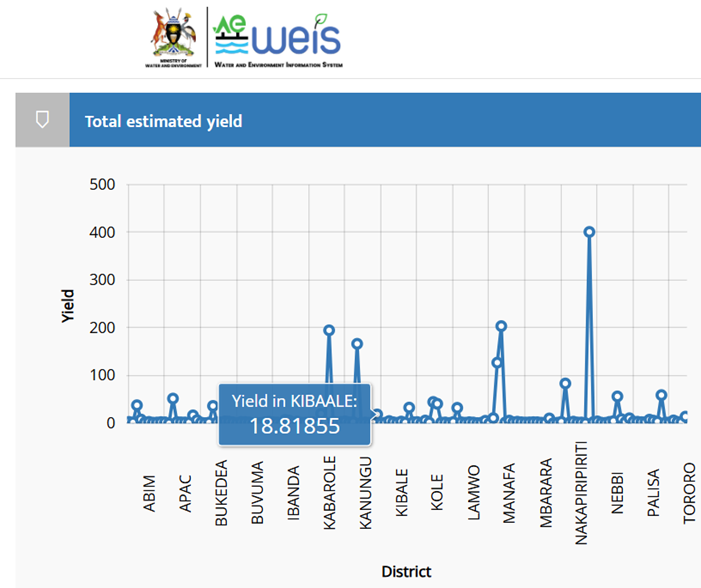

Based on the WEIS data, the average yield capacity of drilled wells in the Kibaale district is 18.8 m3/hr (Figure 2).

This yield capacity should be adequate for the needs of the proposed secondary school campus.

With the yield data showing there is enough groundwater to supply the campus, the team turned their attention to design, and getting the water out of the ground to storage tanks on the surface.

The pump design needs two main ingredients: H, pump head (m) and Q, Flow (L/hr). The pump head (H), or the difference between the groundwater level and the water storage tank level onsite, was estimated to be around 100m. This was based on existing drilling reports recorded and catalogued at ministry sites that other EMI project teams had served elsewhere in Uganda.

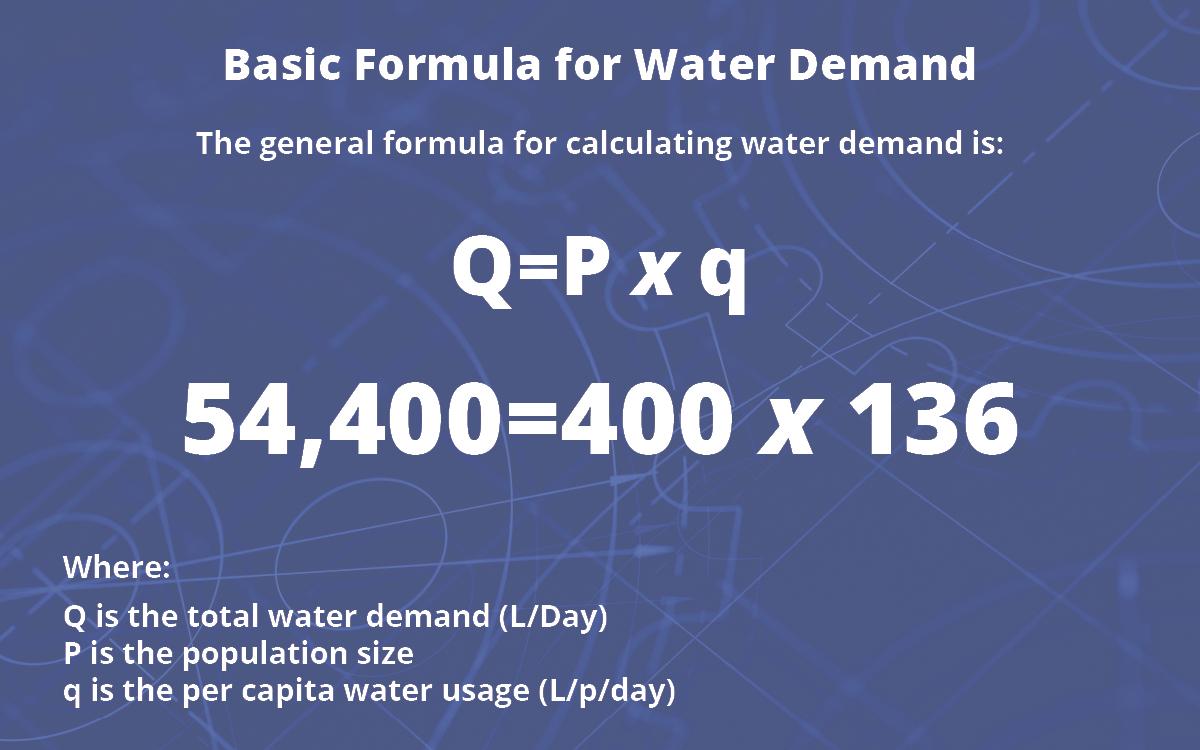

The projected Flow Rate (Q) was estimated using a standard liters per person per day (L/p/day) design approach based on the various activities requiring water at the school, such as laundry or cooking.

The average daily water demand (ADD) for the site was determined to be about 54,514 L/day.

With the pump head (H=100m), flow (Q=54,514L/Day), and estimate yield capacity (18.8 m3/hr) known, the last step was to design the pump curve that would meet these design parameters. A final factor to consider when designing the pump curve is how will the pump be powered? Since the BTCM site is located in a remote area, a medium-sized horsepower pump (>5hp) would be possible but not an ideal solution. This type of pump would be expensive both to purchase but also to run with its daily demand for power. The solution to this was to select a solar powered pump which costs less to purchase and to run.

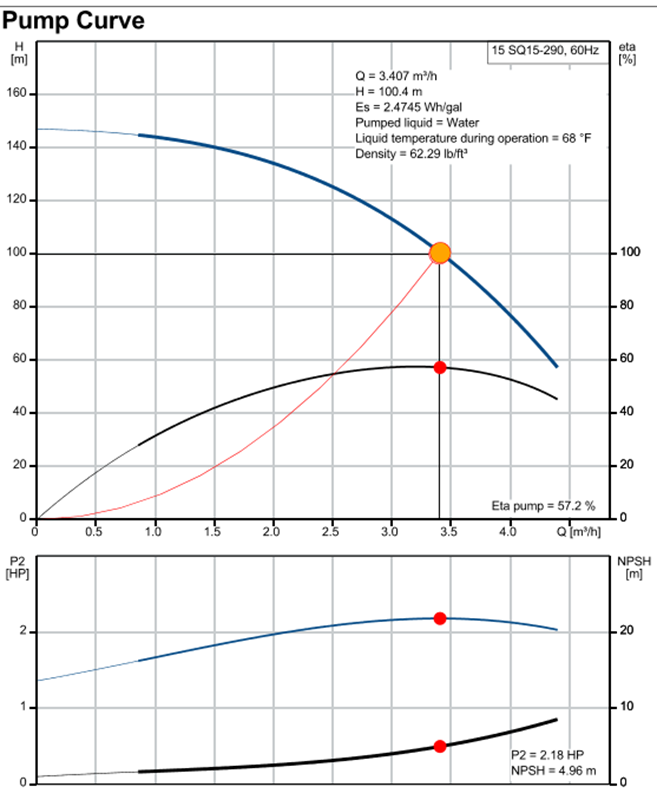

Fortunately, there is a brand of pump that is commonly used in Uganda that meets BTCM’s needs. Grundfos, a pump manufacturer out of Denmark, is readily available for purchase in Kampala, the capital city of Uganda. Our project team researched the available pumps on the Grundfos website to find a pump that met the design parameters of the BTCM secondary school, as seen in Figure 3 below.

The chosen pump, a 15 SQFlex-290 Grundfos solar pump, was designed at a duty point of 3.4 m3/hr at a pump head of 100 m, which is also about the maximum efficiency point of the pump (57.2%). At that flow rate the pump needs to run about 16 hours/day to fill the onsite water storage tanks once the campus is fully built and in operation. Of those 16 hours of pumping, 12 hours would be primarily powered by solar energy, with a secondary connection to the electrical grid to provide backup power during the day and primary power for the four hours of pump time needed after sunset.

In designing the borehole pump system, the team chose to use conservative estimates for borehole depth and water needs. The benefit of being conservative in their approach means that if the actual groundwater level of the borehole ends up being <100 m the chosen pump would still work. For example, if the borehole is only 60 m deep, this would result in an increase of Q to about 4.5m3/hr which, with the chosen pump, means a reduction of the pump time from 16 hours down to 12 hours daily, as indicated in the pump curve in Figure 3. Not only that, but Figure 2 estimates a yield capacity in Kibaale district of 18.8 m3/hr, which is more than capable of supplying water to the secondary school at the potential increased flow rate.

Technical challenges like this represent some of the value an EMI project team brings when serving with ministries around the world. By finding contextually appropriate solutions, EMI designs are sustainable, robust, reliable, redundant, and affordable, allowing ministries to focus on their mission in the community.

We encourage anyone who is interested in working to find solutions to these kinds of challenges to consider joining an EMI project trip.